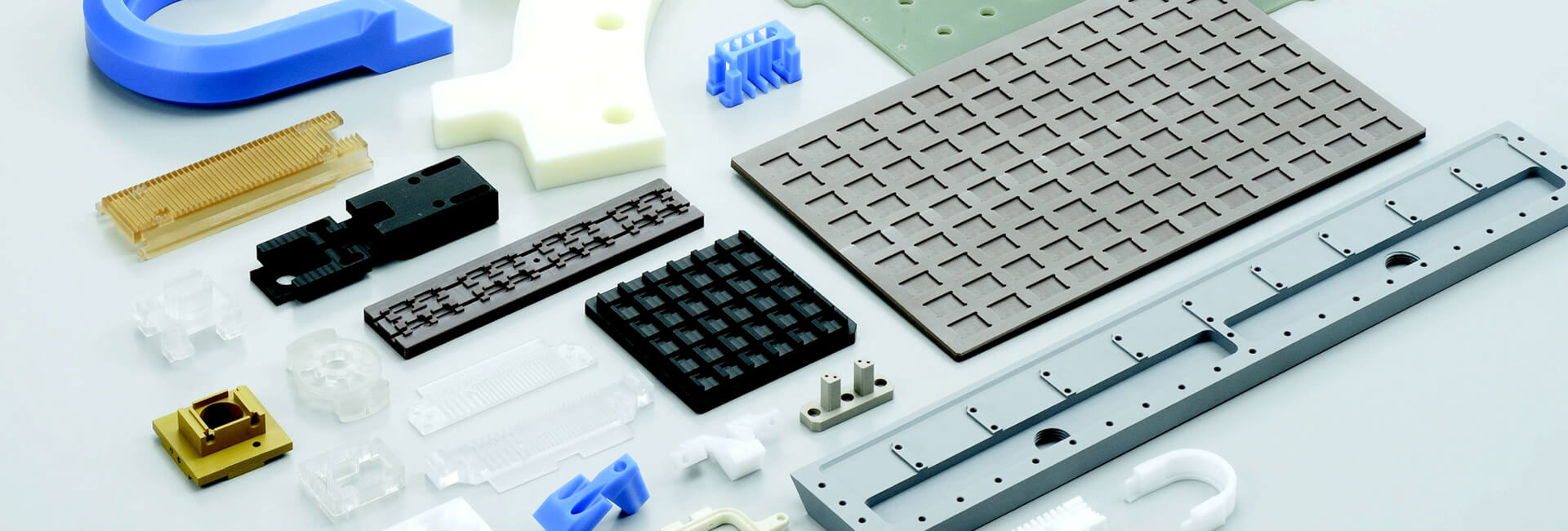

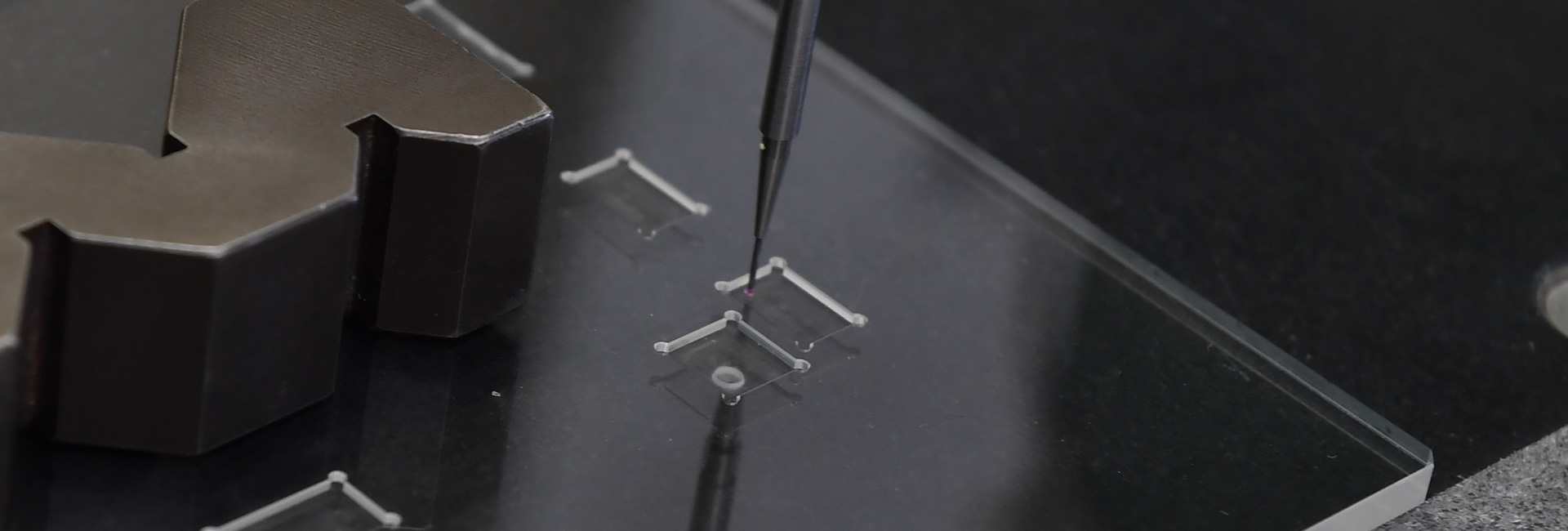

プラスチック材の精密切削加工全般

指先に載るような極少部品から複雑な形状の大型部品まで、

また数も試作1個から量産まで、フレキシブルに対応しております。

052-819-1130受付時間 平日9:00~17:00

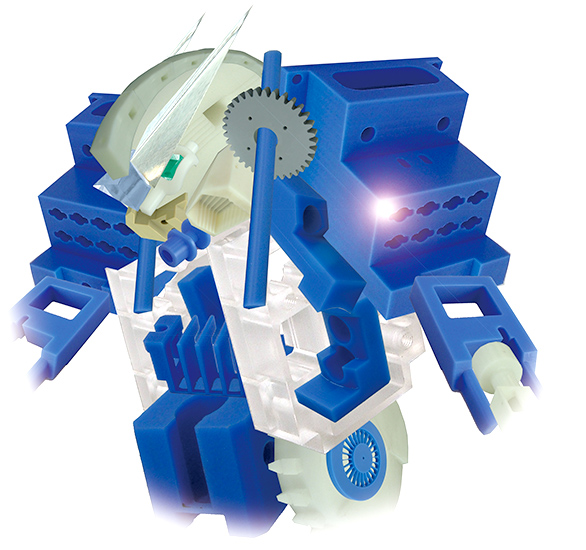

無理難題が多ければ多いほど、職人魂に火がつくのが私たちテクノプラストマン。人・技・最新設備でオンリーワンのシゴトをご提供します

テクノプラストではお客様のご要望にお応えして、オリジナル製品の開発・製造・販売を行っております。

「材料の無駄を省きたい」「こんな製品を作って欲しい」などご要望もお聞かせください。